FEATURES

|

|

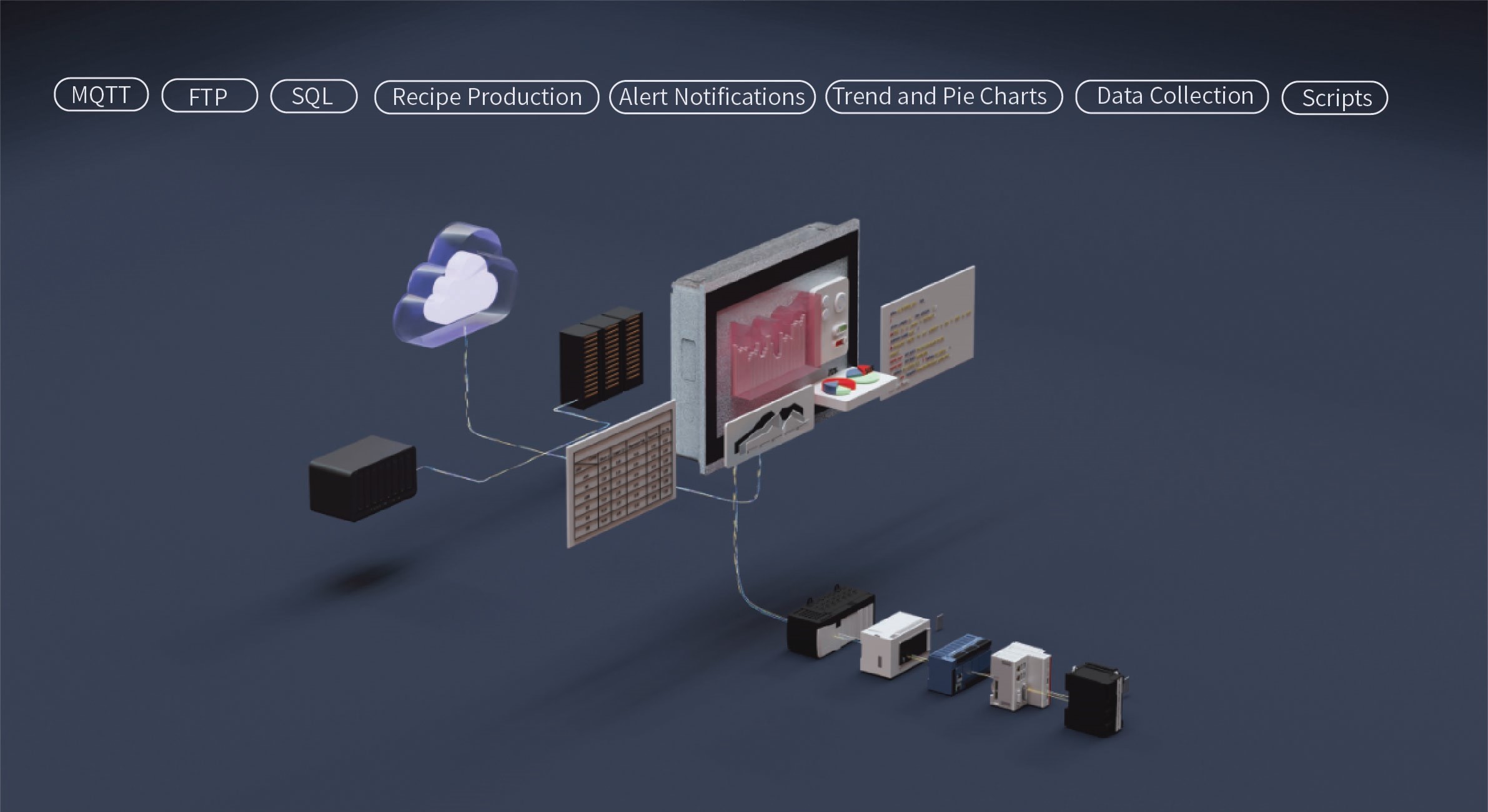

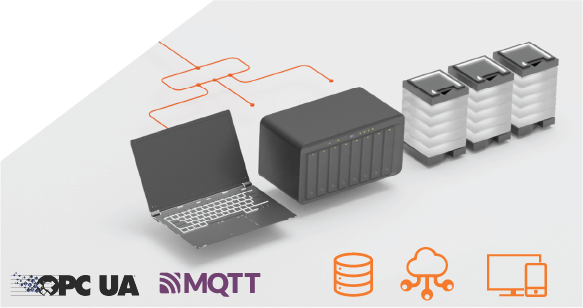

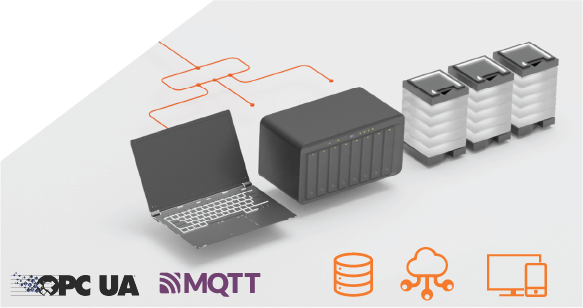

IoT and Databases

Data can be stored in the IoT cloud through the HMI, and data backup and transfer can also be achieved using SQL databases. Support for various protocols such as FTP, VNC, OPC UA, MQTT, and REST API.

FTP Server

Enable the FTP server, allowing users to access the equipment remotely without the need to be physically present. By using a personal computer connected via Ethernet, it is easy to read from or write to the HMI's data files.

Data Collection and ECG Mode

▸ Supports data collection and can display data visualization in various forms such as line charts, pie charts, and bar charts;

▸ In addition to storage on the HMI, USB, and SD cards, data can also be exported via iAccess, FTP, USB, and email.

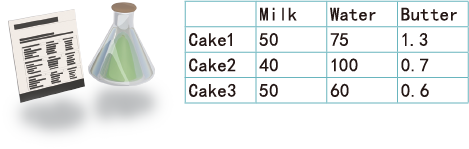

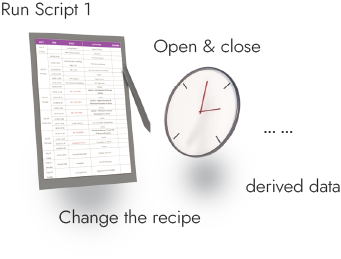

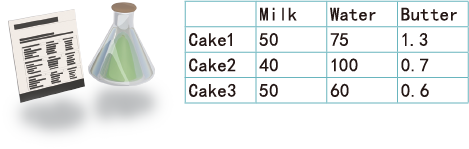

Recipe

▸ HMI stores multiple data sets for PLC transmission.

▸ Imports recipe data from CSV files, no manual entry required.

▸ Features a built-in editor for recipe content.

▸ Offers practical controls for recipe selection.

▸ Enables dynamic recipe updates and edits.

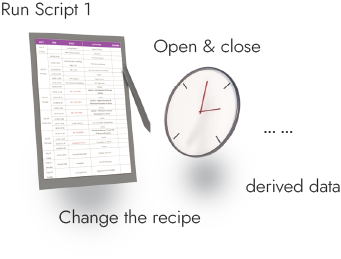

Scheduling

▸ Set up to 64 schedules for preset or dynamic event triggering.

▸ Post-trigger actions: bit setting/clearing, byte writing, script execution.

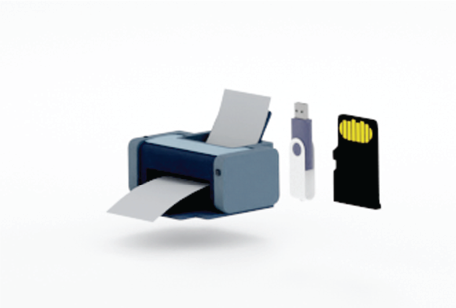

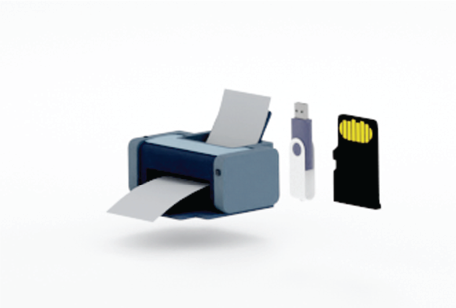

Screenshot and Printing

▸ Project screens can be printed or saved to HMI, SD cards, and USB devices.

▸ Users can select screen areas and apply transformations like rotation and color inversion.

▸ Printing can be triggered by function keys or scripts, with the ability to cancel at any time.

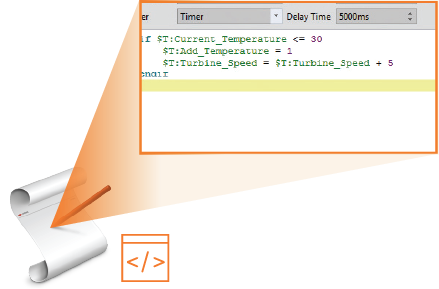

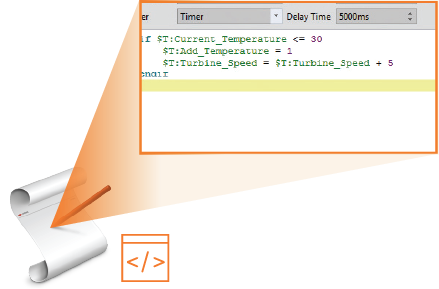

Scripting

▸ Scripts enable complex task automation.

▸ Includes logic, math, loops, strings, and communication.

▸ Allows custom functions and script import/export.

▸ Shows real-time compilation for easy debugging.

▸ Protects scripts with password security.

Support for Dynamic Graphics and PDF Viewer

The dynamic graphics feature allows real-time display of on-site production status.Assists on-site personnel in quickly identifying the location of errors when an alarm occurs.Displays PDF manuals on HMI, no need for physical or electronic files.

Alarm Troubleshooting

Can view equipment status in real-time, even from a distance.

Supports access from various devices including browsers, Android, and iOS.Notifies via E-mail and SMS in case of equipment abnormalities.

|

|

IoT and Databases

Data can be stored in the IoT cloud through the HMI, and data backup and transfer can also be achieved using SQL databases. Support for various protocols such as FTP, VNC, OPC UA, MQTT, and REST API.

FTP Server

Enable the FTP server, allowing users to access the equipment remotely without the need to be physically present. By using a personal computer connected via Ethernet, it is easy to read from or write to the HMI's data files.

Data Collection and ECG Mode

▸ Supports data collection and can display data visualization in various forms such as line charts, pie charts, and bar charts;

▸ In addition to storage on the HMI, USB, and SD cards, data can also be exported via iAccess, FTP, USB, and email.

Recipe

▸ HMI stores multiple data sets for PLC transmission.

▸ Imports recipe data from CSV files, no manual entry required.

▸ Features a built-in editor for recipe content.

▸ Offers practical controls for recipe selection.

▸ Enables dynamic recipe updates and edits.

Scheduling

▸ Set up to 64 schedules for preset or dynamic event triggering.

▸ Post-trigger actions: bit setting/clearing, byte writing, script execution.

Screenshot and Printing

▸ Project screens can be printed or saved to HMI, SD cards, and USB devices.

▸ Users can select screen areas and apply transformations like rotation and color inversion.

▸ Printing can be triggered by function keys or scripts, with the ability to cancel at any time.

Scripting

▸ Scripts enable complex task automation.

▸ Includes logic, math, loops, strings, and communication.

▸ Allows custom functions and script import/export.

▸ Shows real-time compilation for easy debugging.

▸ Protects scripts with password security.

Alert Notifications Troubleshooting,

and Analysis

| Stpe1 Customizable Alarm Conditions |

|

|

Stpe2 Alarm Trigger Alarm Marquee and Data Display |

|

|

Stpe3 Alarm Notifications AReceive notifications via APP, SMS, and Email. |

|

|

Stpe4 Alarm Resolution Monitor the on-site situation with a camera and |

|

|

Stpe5 Error Analysis Utilize features such as data collection, |

|

Support for Dynamic Graphics and PDF Viewer

The dynamic graphics feature allows real-time display of on-site production status.Assists on-site personnel in quickly identifying the location of errors when an alarm occurs.Displays PDF manuals on HMI, no need for physical or electronic files.

Alarm Troubleshooting

Can view equipment status in real-time, even from a distance.

Supports access from various devices including browsers, Android, and iOS.Notifies via E-mail and SMS in case of equipment abnormalities.