Spraying Machine

A spraying machine is a specialized coating equipment that utilizes spraying technology. Its principle involves controlling the airflow to instantly change the direction of the air distribution device, thereby enabling the piston of the pneumatic motor to perform a stable and continuous reciprocating motion. This process pressurizes the inhaled coating material, which is then transported through a high-pressure hose to the spray gun of the spraying machine. The spray gun instantly atomizes the coating material and releases it onto the surface of the object to be coated. The spraying machine mainly consists of a feeding device, a spray gun, and an atomization source. It is suitable for various industries such as leather handbags, gift packaging, furniture, footwear, and automobile manufacturing. On the other hand, automatic spraying equipment is a specialized tool that automatically applies protective or decorative layers to metal and non-metal surfaces, replacing manual labor with intelligent technology.

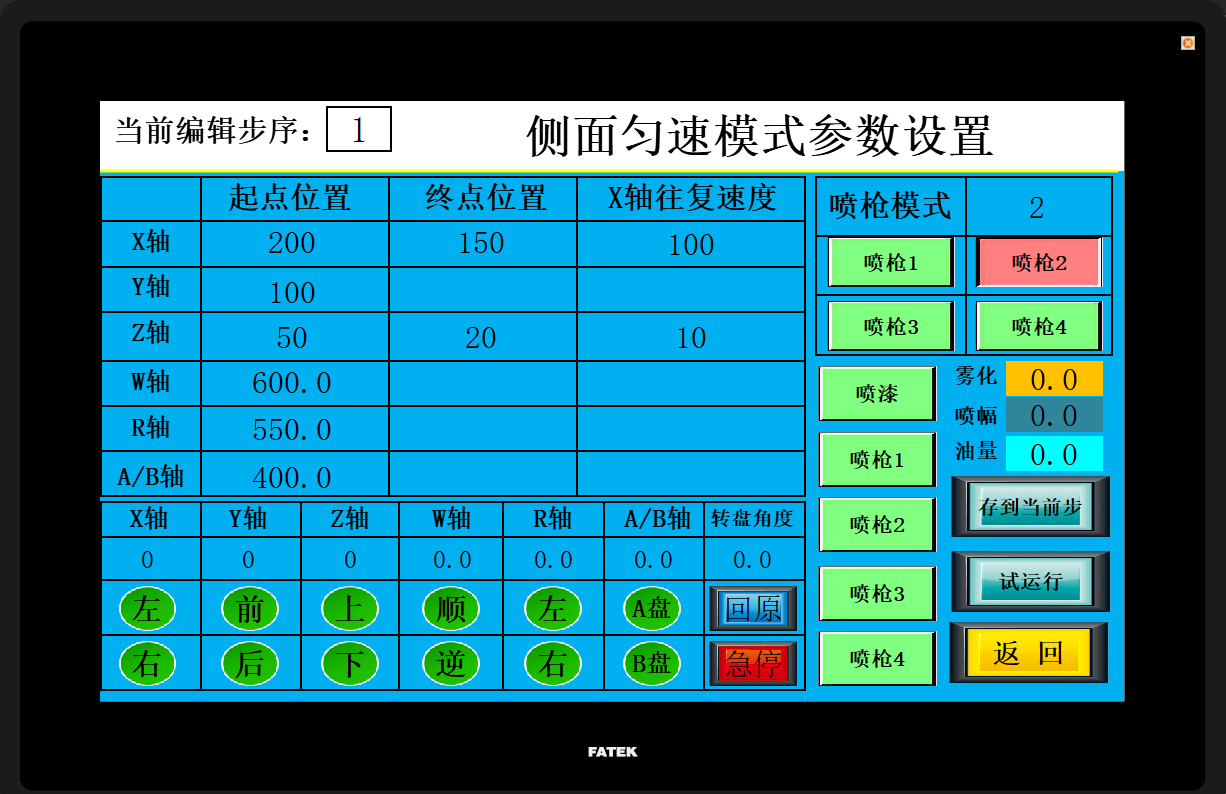

▸ The fully automatic five-axis spraying machine utilizes various spraying processes such as fixed-point spraying and reciprocating spraying. It offers a dozen spraying modes including transition mode, linear reciprocating mode, planar reciprocating mode, and planar inching mode. By setting parameters like spraying positions, spraying modes, and spraying frequencies, the machine achieves automatic spraying functionality.

▸ Since the products that require spraying may have diverse shapes, it is necessary to configure different spraying paths and methods for processing different products. Additionally, the ability to define spraying recipe names on a touchscreen interface is essential.

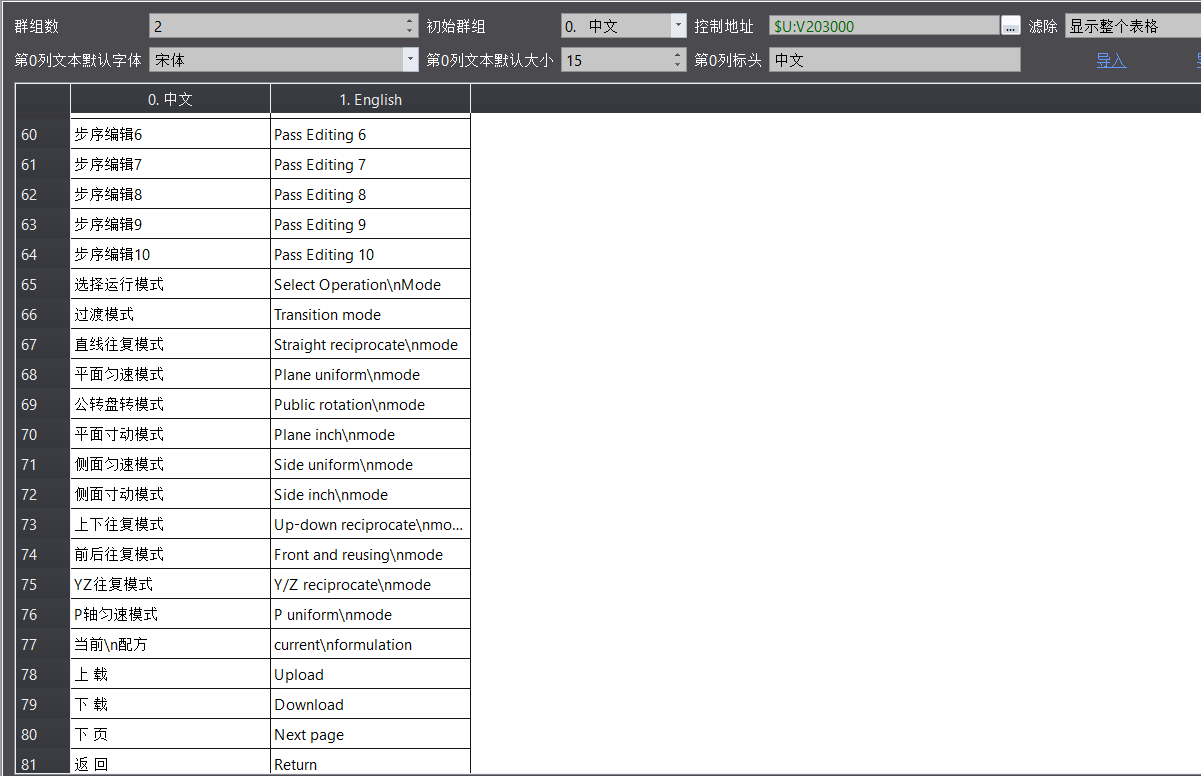

▸ Given that the equipment may be used in the foreign trade market, it is crucial that the display interface supports multiple language functions for seamless switching.

▸ Due to the involvement of numerous nested configurations and customized step sequences in spraying processes, such as reciprocating spraying (side) followed by reciprocating spraying (straight line), and then fixed-point spraying - these are just one of the many scenarios. The order and content of spraying need to be modifiable through an interface. Traditional methods alone can be challenging to achieve this requirement, so we adopt a combination of recipes and scripts. First, we plan out the configured register ranges (spraying methods and parameters). Subsequently, we stack the parameters required for the path settings to be executed. Finally, the machine operates according to the set path sequence.

▸ The keyboard operation allows for the customization of mode configurations to match the specific action patterns desired by the customer. This ensures convenient operation for the customer and tailors the experience to their specific needs. By configuring the keyboard settings according to the customer's preferences, the machine can respond to their inputs efficiently and accurately, providing a seamless and intuitive user interface.

▸ The functionality required for this task is relatively straightforward and can be achieved using the built-in "Text Library" component within the HMI. This component enables the switching of displayed languages across multiple options, currently supporting up to 16 different languages. To expedite the translation process, we can utilize the import and export capabilities of Excel files, allowing for a more efficient translation mapping. This approach ensures a seamless and user-friendly experience for customers across different linguistic backgrounds.

“Custom keyboard”

The keyboard's open design allows for complete freedom in arranging the layout and content of the keys, tailored to meet the diverse needs of customers. This flexibility ensures that the keyboard can be easily customized to fit any specific requirement, providing a user-friendly interface for a wide range of applications.

“Flexible and versatile script control”

By seamlessly integrating recipes with scripting, we achieve customized spraying sequence control, enabling diverse spraying actions for a variety of products. This combination of recipe and script offers unparalleled flexibility in programming the spraying machine, allowing for precise and efficient operation.

“Convenient and fast display of multiple languages”

The ability to quickly and easily switch between multiple languages significantly reduces language-related operational barriers, facilitating the internationalization of the equipment. This feature ensures that users from different linguistic backgrounds can seamlessly interact with the machine, enhancing its global appeal and usability.

Fully automatic spraying is a product of technological advancement and modernization. In the past, the application of adhesives, paint, and other materials was typically done manually or through semi-automatic coating methods. However, these methods suffered from issues such as low precision, poor performance, and a tendency to cause waste and pollution. Automatic spraying machines not only address these concerns but also offer uniform coating, fast speeds, and high spraying efficiency, significantly reducing the amount of time and labor required.

With this equipment, different sequences of actions can be combined to create various recipes, enabling the spraying of different products with desired effects. Furthermore, the inclusion of a multi-language design makes the machine more accessible and appealing on the international stage, paving the way for its widespread adoption and use across borders.