Wind power generation

Wind power generation refers to converting the kinetic energy of wind into electrical energy. Wind energy is a clean, pollution-free, and renewable resource that has been utilized by humans for a long time, primarily through windmills for tasks such as pumping water and grinding grain. Nowadays, there is increasing interest in harnessing wind power for electricity generation. The use of wind power for electricity generation is environmentally friendly and holds tremendous potential given the vast reserves of wind energy, making it increasingly valued by countries worldwide. To further promote the development of wind power in the country, enhance public scientific literacy, and encourage more aspiring young people to devote themselves to the green wind power industry, some small-scale facilities for wind power generation have been introduced in places such as schools, science museums, and factories. These facilities, installed in small-scale settings like schools or factories, must meet the following special requirements while ensuring normal operation for wind power generation:

▸ During wind power generation, it is necessary to regulate and adapt to various changing environmental conditions based on different climatic variations. For instance, in cases of strong winds or other adverse environmental conditions, the equipment should be temporarily suspended for protection. This requires the collection and utilization of data from sensors such as wind speed sensors and wind direction sensors. Additionally, the system should support the display of historical data curves to facilitate the observation of data trends, and the sensor data should be saved on a daily schedule.

▸ To enable a more intuitive observation of the on-site equipment's operational status, the device needs to be equipped with a camera for real-time monitoring. It is desired that even remotely, through devices such as apps or PCs, users can access real-time video information via the internet.

▸ To prevent equipment damage during extreme weather conditions, the device should have a braking mode that can be activated in special circumstances to prevent accidents. Considering that there may not always be personnel nearby to manually activate the brakes in emergency situations, a remote control braking function is required. This allows users, even those located in different provinces, to control the start and stop of the brakes through the internet of things.

▸ The touchscreen data acquisition function enables periodic collection of data from corresponding wind speed and wind direction sensors. Additionally, through the historical trend chart component, the collected data can be presented in a graphical format for easy monitoring. To save the data, the export data function can be utilized to set a scheduled task that automatically saves the data to the internal memory of the touchscreen or an external USB drive at 17:30 every day.

▸ By connecting the touchscreen to the school's switch through a network cable, all computers within the school's internal network can access the touchscreen as they are all connected to the same switch and within the same network segment. Through the touchscreen's transparent function, operations such as monitoring and modifying PLC programs can be achieved.

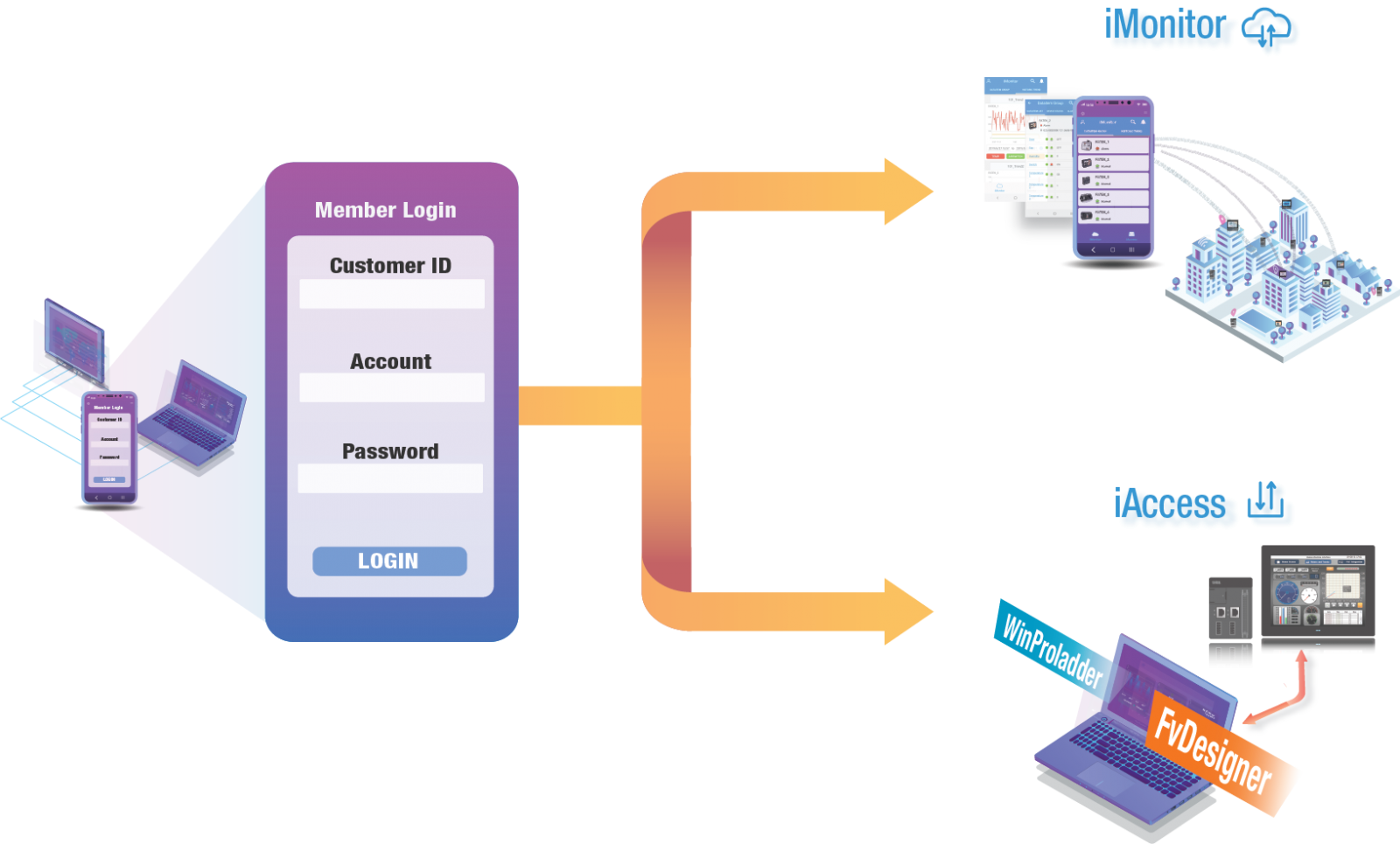

▸ To save costs, a USB-type camera is utilized. The Yonghong touchscreen supports USB camera input, eliminating the need for a separate power supply for the camera. By pairing it with a video input display component, real-time footage can be streamed and displayed on the touchscreen interface. Remote video access can be achieved through the remote screen monitoring function in IOT iAccess, which allows users to view the actual touchscreen display remotely via an app or PC software.

▸ To prevent damage to the equipment during adverse weather conditions when no personnel are present, remote control capabilities are necessary. Through IOT iAccess, a brake control signal can be programmed for remote control. Additionally, remote access to the HMI (Human-Machine Interface) screen allows for the activation of the brake button on the operation interface, addressing the issue of unmanned maintenance during abnormal weather conditions.

“Visual Data Display”

Sensor data is displayed intuitively, eliminating the need to deal with tedious raw numbers through data visualization.

“Real-time Observation of Equipment Status”

Using a USB camera, live footage is streamed to the touchscreen interface, combined with the remote video functionality of the iAccess screen monitoring feature.

“Remote Control of Equipment”

Through the screen monitoring and data control functions of iAccess, equipment operations can be remotely controlled.

Users can monitor real-time wind speed and direction data from the equipment site directly on the touchscreen. Additionally, historical trend charts are available to visualize real-time and historical data in a graphical format, providing an intuitive and visual representation of the data. Through the camera, users can observe the real-time operation of the equipment, and with the iAccess feature, they can conveniently access remote video monitoring and remotely operate the equipment.