Wastewater Treatment

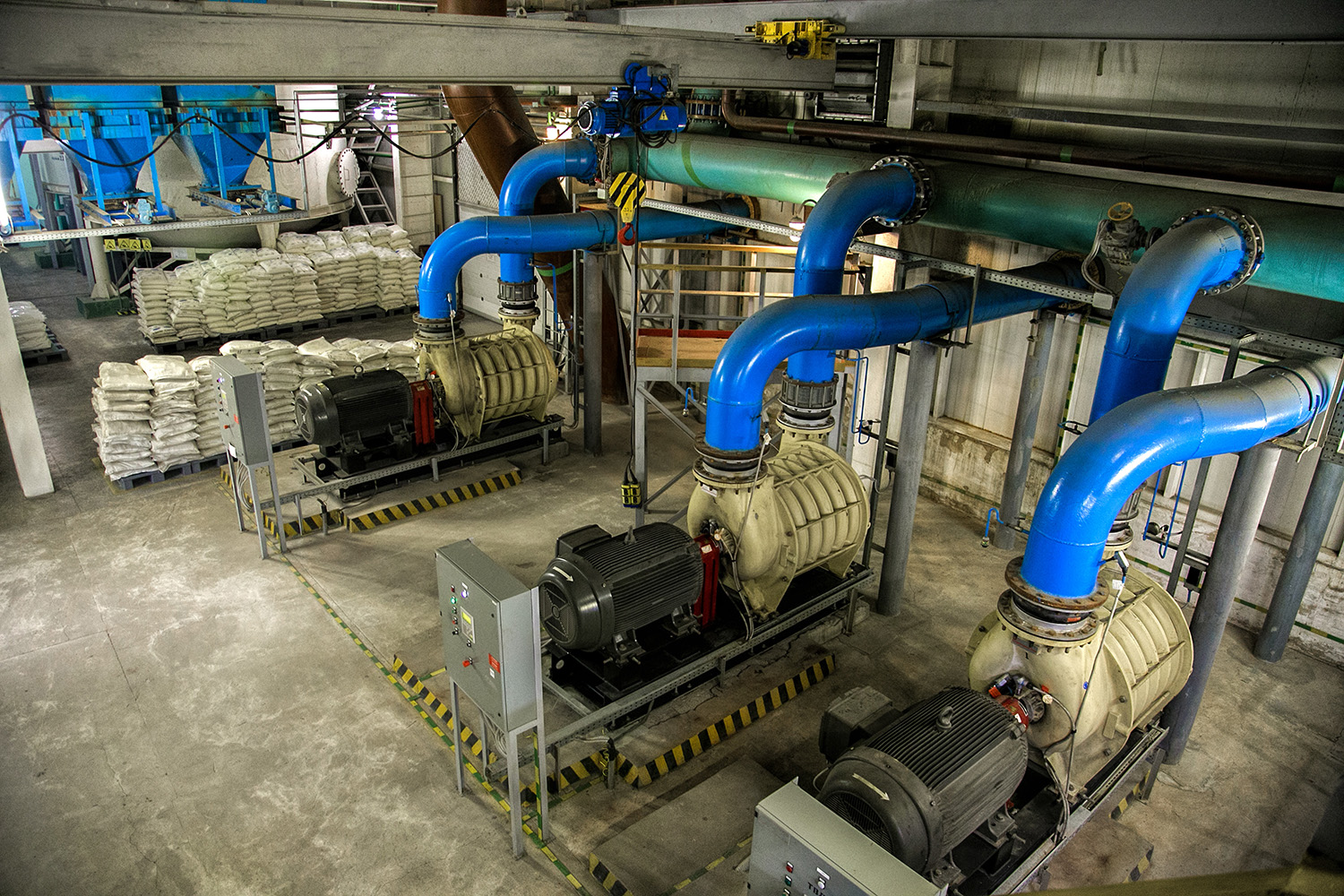

Wastewater treatment is the process of purifying water to meet the quality standards required for discharging into a water body or for reuse. This treatment is widely applied in various fields such as construction, agriculture, transportation, energy, petrochemicals, environmental protection, urban landscaping, healthcare, catering, and increasingly, it has become a part of everyday life for ordinary people. Wastewater treatment can be categorized into three main methods based on their functions: physical, biological, and chemical.

▸ We hope to have an interface that directly displays the entire water treatment process and sensor data from each station, allowing on-site personnel to monitor clearly and effectively.

▸ The interface should clearly indicate the pipeline layout and the status of water valves, as well as visually show whether sewage is flowing. The main screen should include the pipeline layout diagram, with corresponding indicators displayed during the processing of each station.

▸ The factory needs to adopt online monitoring equipment to generate and collect various monitoring data in real-time (such as 24-hour influent and effluent water quality, sludge data, etc.), with support for data export and storage.

▸ Due to the complexity and numerous steps involved in the water treatment process, along with the distribution of various sensors across different workstations, the implementation of SCADA (Supervisory Control and Data Acquisition) on a PC computer is adopted on-site. This system allows for the display of the entire workflow of workstations in water treatment, along with the parameters of their respective sensors.

▸ While it is possible to implement pipeline diagrams through image functions by directly importing PNG files of the pipeline, this method often results in unsightly and complex manipulations as each bend and intersection needs to be carefully pieced together. To address this issue, built-in tubular graphics can be utilized. With these graphics, one can simply click with a mouse to plan the path and quickly generate a pipeline diagram. The tubular elements on a touchscreen interface offer even more convenience, allowing for signal-based manipulation of various colors within the pipes and quick setup of dynamic flow effects. This not only enhances the visual aesthetics with a more dynamic look but also allows for a quick understanding of the operational status of each workstation through the colors within the pipes.

▸ Through the data collection function in the SCADA software, uninterrupted data acquisition can be achieved 24 hours a day. Not only can the collected data be visually presented through historical trend charts, but also, with the FTP transmission function, the data information can be regularly sent to other PCs on the local area network or saved to the current computer. This allows for system backup data and effective access to data history.

“SCADA Graphical Control Software”

Leveraging the powerful computing capabilities and system architecture of industrial computers, coupled with various screen sizes, the computer can be transformed into a robust monitoring center.

“User-Friendly Tubular Graphic Configuration”

Not only can the color inside the pipes be dynamically modified, but also flow effects can be added, enhancing the dynamic aesthetics.

“Data Collection and Storage”

Regular data collection, combined with FTP functionality, enables system backup and effective access to data history.

Utilizing the powerful computing capabilities and system architecture of industrial computers through the SCADA software, coupled with various screen sizes, the computer can be transformed into a robust monitoring center, clearly displaying the entire workflow of workstations and sensor information. The use of tubular graphic components enhances the aesthetics of the interface and adds dynamic flow effects, allowing for a quick understanding of the operational status of each workstation through the colors within the pipes. Regular collection of sensor data and access to data history improve the efficiency and reliability of data management in wastewater treatment plants.